Indlela yokufaka i-gutter yokwakha isakhiwo sentsimbi?

Izixhobo kunye nokusetyenziswa

1. Izinto:

Okwangoku, kukho izinto ezintathu ezisetyenziswa ngokuqhelekileyo: i-gutter yentsimbi enobunzima be-3 ~ 6mm, i-gutter yensimbi engenasici kunye nobukhulu be-0.8 ~ 1.2mm kunye nombala wentsimbi ye-0.6mm.

2. Isicelo:

Igatha yepleyiti yentsimbi kunye negutter yentsimbi engatyiwayo ingasetyenziswa kwiiprojekthi ezininzi.Phakathi kwabo, i-gutter yensimbi engenasici isetyenziswa ngokuqhelekileyo kwiindawo eziselunxwemeni kunye neendawo ezinerhasi eyomeleleyo enomhlwa kufuphi neprojekthi;Umjelo wepleyiti yombala usetyenziswa ikakhulu kumjelo wangaphandle wesakhiwo segesi kunye neeprojekthi ezinommandla omncinci wobunjineli kunye nokuhambisa amanzi amancinci.Idla ngokusetyenziswa njengegutter yangaphandle.

Indlela yokudibanisa

★ umjelo wentsimbi yentsimbi

1. Imiqathango yokufakela:

Ngaphambi kokufaka i-gutter yensimbi yentsimbi, le miqathango ilandelayo kufuneka ihlangabezane nayo: umzimba oyintloko wesakhiwo sensimbi (i-beam kunye nekholomu) ifakwe kwaye ilungelelaniswe, kwaye zonke iibholiti eziphezulu eziphezulu ziye zagqitywa ekugqibeleni.Kwiprojekthi eneparapet, ikholomu yeparapet kunye nodonga oluhambelanayo lufakwe kwaye luhlengahlengiswe.Igatha yentsimbi yentsimbi sele ikhona.Oomatshini bokuwelda bombane kunye neentsimbi zokuwelda sele zikhona.

2. Ukuhlohla:

Emva kokuba i-gutter yentsimbi ehambelanayo ihanjiswe kwindawo ngokwemizobo yoyilo, i-gutter iya kuhanjiswa kwindawo ekhethiweyo yokufakela nge-crane okanye ukuthuthwa ngesandla ngokobukhulu kunye nobunzima be-gutter, kwaye i-gutter iya kudibaniswa okwethutyana nge-welding yombane. ngoko nangoko.Xa zonke izixhobo zombhobho zimi endaweni, zoba umgca wokunqumla ngocingo lwentsimbi ngaphandle komjelo, kwaye ulungelelanise amacala angaphakathi nangaphandle egatha yonke kumgca othe ngqo ofanayo.Ngexesha lohlengahlengiso, qaphela ukunciphisa i-gap kwi-joint gutter, kwaye uyilungise okwesikhashana nge-welding yombane.Emva koko weld ngokupheleleyo intsimbi esezantsi ethe tye kunye ne-weld ethe tye kumacala omabini ngentonga ye-welding enobubanzi obuyi-3.2mm.Ngexesha lokutshisa, nikela ingqalelo kumgangatho we-welding kwaye ulawule i-welding current, Ukuthintela ukutshisa nge-gutter kunye nokwandisa inkathazo engeyomfuneko.I-welding engapheliyo ingasetyenziselwa ukudibanisa phakathi kwezantsi kwe-gutter kunye nephezulu yekholomu.I-bottom of gutter kunye nephezulu yekholomu yensimbi inokudityaniswa kwaye ilungiswe ukwandisa ukuqina okupheleleyo.I-gutter engakwazi ukuxutywa ngosuku olufanayo inokulungiswa okwethutyana nge-welding yombane kunye neendlela ezingentla.Ukuba iimeko ziyavuma, igatha inokubotshwa kwaye ilungiswe ngomqadi wodonga okanye isibiyeli somjelo ngentambo yentsimbi.

3. Ukuvulwa kwendawo yokuphuma:

Umjelo wokuphuma kwamanzi uya kubekwa ngokweemfuno zoyilo.Ngokuqhelekileyo, i-outlet yesiqhelo iya kuvulwa kwicala lekholomu yensimbi okanye intsimbi yentsimbi.Nikelani ingqalelo kwindawo yenkxaso xa uvula umngxuma, kwaye uzame ukuwuphepha kangangoko kunokwenzeka, ukuze unciphise inani lezesekeli ze-downpipe.Indlela yofakelo yombhobho osezantsi iya kuqwalaselwa ngelixa uvula.Kungcono ukumisela indlela yokulungisa i-hoop ye-downpipe kuqala, ukwenzela ukuba unciphise izinto zokulungisa i-hoop kunye nokunciphisa iindleko.Umngxuma unokuvulwa ngokusika igesi okanye i-angle grinder.Kunqatshelwe ngokungqongqo ukuvula umngxuma ngokuthe ngqo nge-welding yombane.Emva kokuba umgodi uvuliwe, i-shaft kunye ne-periphery yomgodi iya kuhlanjululwa nge-grinder ye-angle, kwaye emva koko ukuphuma kwamanzi kumbhobho wensimbi kuya kuxutywa kunye ne-gutter.Nika ingqalelo kumgangatho we-welding ngexesha le-welding ukukhusela ukulahleka kwe-welding.Emva kwe-welding, i-welding slag iya kucocwa kwangethuba, kwaye intsimbi ye-welding iphezulu kakhulu kunombhobho iya kupholiswa nge-angle grinder de ibe tyaba.Ukuze kuthintelwe ukuqubha kwindawo yokuphuma amanzi, ihamile ingasetyenziselwa ukutyumza indawo yokuphuma amanzi ukuze kube lula ukukhupha amanzi.

4. Peyinta:

Emva kokuba onke ama-gutters adibeneyo kwaye ahlolwe ukuba afaneleke, i-welding slag kwindawo yokudibanisa iya kuhlanjululwa ngokupheleleyo kwakhona.Ngelo xesha, ipeyinti kwindawo ye-welding iya kuhlanjululwa nge-brush yensimbi, kwaye emva koko ilungiswe ngepeyinti ye-antirust yenkcazo efanayo kunye nepeyinti yokuqala.Ukugqitywa kwegutter kuya kupeyintwa phambi kolwakhiwo lwephaneli yophahla ngokweemfuno zoyilo.Ukuba akukho mfuneko yoyilo, omnye umaleko we-neoprene uya kupeyintwa kwicala langaphakathi lomsele weplate yentsimbi ukwenzela unyango lokuchasana nomhlwa.

★ ukufakwa kwegutter yensimbi engenasici

1. Iimeko zofakelo kunye neemfuno zokuvula umbhobho ophantsi we-gutter yensimbi engenasici ziyafana nezo zentsimbi yentsimbi.

2. I-Argon arc welding yamkelwa kwi-welding ye-gutter yensimbi engenasici, kunye nocingo lwensimbi engenasici kwizinto ezifanayo kunye ne-gutter yamkelwe njengentonga ye-welding, kwaye ububanzi bunokufana nobukhulu beplate.Ngokuqhelekileyo 1mm.Ngaphambi kwe-welding esemthethweni, i-welders iya kuququzelelwa ukuba iqhube i-welding yovavanyo, kwaye i-batch welding inokuqaliswa kuphela emva kokuphumelela uvavanyo.Ngexesha elifanayo, kukulungele ukutyumba abasebenzi abakhethekileyo kwi-welding, kwaye ulungiselele umsebenzi oncedisayo ukuba asebenzisane nokusebenza, ukwenzela ukuba kuphuculwe ukusebenza kakuhle kwemveliso ephambili.Emva kokuba i-outlet yamanzi idityanisiwe, indawo kufuneka iphinde ibhujiswe ngokufanelekileyo ukuze kube lula ukukhupha amanzi.Ukuba kukho intlenga kunye nolunye ungcoliseko kwi-electrode yensimbi engenasici, kufuneka isuswe ngaphambi kokusetyenziswa.

3. Ngenxa yokuba i-gutter yensimbi engenasici icutshungulwa kwaye yenziwe ngokugoqa, akunakuphepheka ukuba kukho ukuphambuka kwe-dimensional.Ngoko ke, ngaphambi kokuba i-gutter ihanjiswe, iya kuhlolwa ngokubanzi ukunciphisa i-gap kwi-joint.Ngaphambi kwe-welding, iya kulungiswa nge-welding yendawo, kwaye emva koko ifakwe.Umphantsi we-gutter uya kuxutywa, kwaye icala le-gutter liya kuxutywa.Ukuba kunokwenzeka, ulungiselelo lwesilingo lunokwenziwa, kwaye ukunyuswa kunokwenziwa emva kokubala iinombolo ngokwelungiselelo lovavanyo, ukuze kuncitshiswe umsebenzi we-welding kunye nokuqinisekisa umgangatho weprojekthi.Ukuba i-gap inkulu kakhulu ukuba ifakwe ngokupheleleyo nge-welding wire, inokudityaniswa ngezinto ezishiyekileyo.Kuyimfuneko ukuba i-weld ijikeleze i-splice, kwaye uqinisekise ukuba i-welds emaphethelweni kunye neekona zigcwele ngaphandle kokulahleka.

★ Ukufakwa kwegutter yepleyiti yombala

1. Ukufakwa kwe-gutter yemigodi kunokuqhutywa emva kokufakwa kwe-roof slab okanye ngexesha elifanayo kunye ne-roof slab.Iinkcukacha zinokumiselwa ngokuguquguqukayo ngokwemiqathango yesayithi.

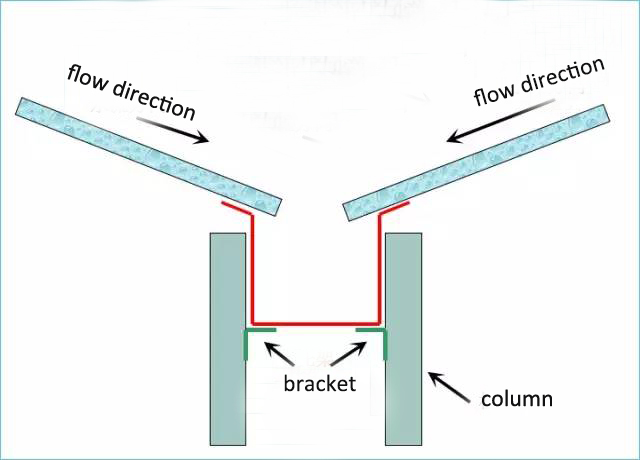

2. Ukulungiswa kombhobho weplate yombala uhlukaniswe ngamacandelo amabini: enye inxalenye kukuba icala langaphakathi lombhobho lidibene nepaneli yophahla kunye ne-self tapping screws okanye i-riveted nge-rivets pull;elinye icala lelokuba umphetho osongekileyo wecala langaphandle lomsele udityaniswe kuqala kunye neerivets zebrace brace, kwaye elinye icala lebrace lidityaniswe nepaneli yophahla kunye ne-purlin ngezikrufu zokuzicofa ezilungisa ipaneli yophahla kwindawo yophahla. iphaneli yophahla.Ukudibanisa phakathi kwe-gutter kunye ne-gutter ihlanjululwe ngee-rivets kwimiqolo emibini kunye nesithuba se-50mm ngokweemfuno ze-atlas esemgangathweni yenkampani, I-lap joint phakathi kwamacwecwe iya kutywinwa ngokutywinwa okungathathi hlangothi.Ngexesha lokudibanisa i-lap, qaphela ukucocwa kwendawo ye-lap.Emva kwe-gluing, iya kuma ixesha elifutshane, kwaye eyona nto iphambili inokushukunyiswa emva kokuba iglue iphiliswe.

3. Ukuvulwa kwe-gutter outlet kungenziwa ngokuthe ngqo ngomatshini wokusika, kwaye isikhundla siya kuhlangabezana neemfuno zokuyila.I-outlet kunye ne-gutter bottom iya kulungiswa ngokutsalwa kwee-rivets ngokweemfuno zeendawo ezifanelekileyo ze-atlas esemgangathweni, kwaye iimfuno zonyango lwe-sealant kwikhonkco ziya kudibaniswa ne-gutter.

4. Iimfuno ze-flatness ze-gutter yeplate yombala ziyafana nezo zentsimbi yentsimbi.Ngenxa yokuba ubukhulu becala bugqitywe ngumgangatho wofakelo lwesakhiwo esiyintloko, umgangatho wokwakhiwa kwesakhiwo esiphambili kufuneka uqinisekiswe ngaphambi kokuba kufakwe i-gutter, ukuze kubekwe isiseko esihle sokuphucula umgangatho wofakelo lwe-gutter.

Ixesha lokuposa: Apr-03-2022