Indawo yokugcina intsimbi sisisombululo esifanelekileyo sokugcina iimfuno zakho kunye nolawulo, i-mezzanine inokusekwa njengeofisi kumgangatho wesibini ukuhlangabezana neemfuno zeofisi. Ngokuqhelekileyo iqulunqwe ngentsimbi yentsimbi, ikholomu yensimbi, i-purline yensimbi, i-bracing, i-cladding. .Inxalenye nganye edityaniswe zii-welds, iibholiti, okanye iirivethi.

Kodwa kutheni ude ukhethe indawo yokugcina izinto ezenziwe ngentsimbi njengokhetho?

Indawo yokugcina intsimbi vs indawo yokugcina ikhonkrithi yesintu

Owona msebenzi mkhulu wesitora kukugcina impahla, ngoko ke indawo eyaneleyo yeyona nto ibalulekileyo. Indawo yokugcina impahla yentsimbi inobude obukhulu kunye nendawo enkulu yokusetyenziswa, edibanisa eli nqaku. Kwiminyaka yakutshanje, ziya zisanda ngakumbi izakhiwo zentsimbi. ezayo, into ebonisa ukuba oosomashishini abaninzi bayayishiya imodeli yolwakhiwo lwekhonkrithi esele isetyenziswe iminyaka emininzi.

Xa kuthelekiswa neendawo zokugcina izinto zekhonkrithi zesintu, iindawo zokugcina izinto zentsimbi zinokugcina ixesha lokwakha kunye neendleko zabasebenzi.Ukwakhiwa kwendawo yokugcina impahla yensimbi ikhawuleza, kwaye impendulo kwiimfuno ngokukhawuleza ibonakala, enokuthi ihlangabezane neemfuno zokugcina ngokukhawuleza zeshishini. ixabiso, kwaye ikhuseleke ngakumbi kwaye izinzile.

Indawo yokugcina impahla yentsimbi inobunzima, kwaye uphahla kunye nodonga ngamacangci entsimbi okanye ipaneli yesandwich, ezikhaphukhaphu kakhulu kunezo zikudonga lwekhonkrithi yesitena kunye nophahla lweterracotta, ezinokunciphisa ngokufanelekileyo ubunzima bubonke besakhiwo sentsimbi ngaphandle kokubeka esichengeni uzinzo lwayo lwesakhiwo. .Kwangaxeshanye, inokunciphisa iindleko zothutho zamacandelo ezenziwe ngokufuduka ngaphandle kwesiza.

Uthelekiso phakathi kweSakhiwo seNsimbi esenziwe kwangaphambili kunye nesiQhelekileyo.

| Iipropati | Isakhiwo seNtsimbi eSenziwe kwangaphambili | Isakhiwo sentsimbi esiqhelekileyo |

| Ubunzima boLwakhiwo | Izakhiwo ezenziwe ngobunjineli ngaphambili zikhaphukhaphu nge-30% ngenxa yokusetyenziswa kakuhle kwentsimbi. Amalungu eSekondari abubunzima obulula buqulunqwe "Z" okanye "C" amalungu amile. | Amalungu entsimbi ephambili akhethwe amacandelo ashushu "T".Yeyiphi, kumacandelo amaninzi amalungu anzima kunoko kufunwa ngokwenene kuyilo. Amalungu eSekondari akhethwa kumacandelo asemgangathweni ashushu aqengqelekayo anzima kakhulu. |

| Yila | Uyilo olukhawulezayo nolusebenzayo kuba ii-PEB zenziwa ikakhulu ngamacandelo asemgangathweni kunye noyilo loqhagamshelo, ixesha lincitshiswe kakhulu. | Isakhiwo ngasinye sentsimbi yesiqhelo siyilwe ukusuka ekuqaleni kunye nezixhobo ezimbalwa zoyilo ezifumanekayo kwinjineli. |

| Ixesha Lokwakha | Umyinge weeveki ezi-6 ukuya kwezi-8 | Umyinge weeveki ezingama-20 ukuya kwezingama-26 |

| Isiseko | Uyilo olulula, kulula ukwakha kunye nobunzima obulula. | Isiseko esibanzi, esinzima esifunekayo. |

| Ukumiswa kunye nokulula | Ekubeni uxhulumaniso lwee-compounds lusemgangathweni i-curve yokufunda yokwakhiwa kweprojekthi nganye elandelayo ngokukhawuleza. | Uqhagamshelo luhlala luntsonkothile kwaye luyahluka ngokweprojekthi neprojekthi nto leyo ebangela ukuba inkonkxa yonyuse ixesha lokwakhiwa kwezakhiwo. |

| Ixesha lokuMisa kunye neXabiso | Inkqubo yokwakhiwa ikhawuleza kwaye ilula kakhulu kunye nemfuneko encinci kakhulu yezixhobo | Ngokuqhelekileyo, izakhiwo zentsimbi eziqhelekileyo zixabisa i-20% ngaphezu kwe-PEB kwiimeko ezininzi, iindleko zokumisa kunye nexesha aziqikelelwa ngokuchanekileyo. Inkqubo yokwakhiwa icotha kwaye kufuneka umsebenzi omkhulu endle.Izixhobo ezinzima nazo ziyafuneka. |

| Ukumelana nenyikima | Iifreyimu ezinobunzima obuphantsi obubhetyebhetye zinika ukuchasana okuphezulu kumandla enyikima. | Izakhelo ezinzima eziqinileyo aziqhubi kakuhle kwiindawo zenyikima. |

| Phezu kwazo zonke iindleko | Ixabiso nge-square meter nganye linokuba ngaphantsi njenge-30 % kunesakhiwo esiqhelekileyo. | Ixabiso eliphezulu ngemitha yesikwere. |

| Uyilo lwezakhiwo | Uyilo olugqwesileyo loyilo lunokufezekiswa ngexabiso eliphantsi usebenzisa iinkcukacha eziqhelekileyo zokwakha kunye nojongano. | Uyilo olulodwa loyilo kunye neempawu kufuneka ziphuhliswe kwiprojekthi nganye ehlala ifuna uphando kwaye oko kukhokelela kwindleko ephezulu. |

| Ukwandiswa kwekamva | Ukwandiswa kwexesha elizayo kulula kakhulu kwaye kulula. | Ukwandiswa kwexesha elizayo kuyadinisa kwaye kubiza kakhulu. |

| Ukhuseleko kunye noxanduva | Umthombo omnye woxanduva ukho kuba wonke umsebenzi wenziwa ngumthengisi omnye. | Uxanduva oluninzi lunokubangela umbuzo wokuba ngubani onoxanduva xa iikhomponenti zingangeni ngokufanelekileyo, kubonelelwe ngemathiriyeli enganelanga okanye iinxalenye zisilela ekusebenzeni ngokukodwa kujongano lomthengisi/nokontraka. |

| Ukusebenza | Onke amacandelo acacisiwe kwaye ayilwe ngokukodwa ukuba asebenze kunye njengenkqubo yokusebenza kakuhle kakhulu, i-fir echanekileyo kunye nokusebenza okuphezulu kwintsimi. | Amacandelo ayilwe ngokwesiko kwisicelo esithile kumsebenzi othile.Iimpazamo zokuyila kunye neenkcukacha zinokwenzeka xa kuhlanganiswa amacandelo ahlukeneyo kwizakhiwo ezizodwa. |

Uyilo olugqwesileyo lokuthwala umthwalo

Umthamo wokuthwala umthwalo kufuneka uqwalaselwe xa uyilo, ukuqinisekisa ukuba indawo yokugcina impahla yentsimbi inokumelana namanzi emvula, uxinzelelo lwekhephu, umthwalo wokwakha, kunye nomthwalo wokulungisa. Yintoni enye, kufuneka ihlangabezane neemfuno zomthamo osebenzayo, amandla ezinto eziphathekayo, ubukhulu kunye nemo yokuhambisa amandla, ukuthwala umthamo, iimpawu ezinqamlezayo zenguqu, njl.

Iingxaki zokuthwala umthwalo woyilo lwesakhiwo sentsimbi yesitora kufuneka ziqwalaselwe kakuhle ukunciphisa umthamo womonakalo wendawo yokugcina impahla, ukuphumeza ubomi obude benkonzo.

Uyilo olusebenzayo lwamandla

Ukuba indawo yokugcina ikhonkrithi yesiko okanye indawo yokugcina eyenziwe ngamaplanga, ukukhanya kufuneka kukhanyiswe imini yonke nasebusuku, nto leyo ngokungathandabuzekiyo iya kukwandisa ukusetyenziswa kwamandla.kodwa kwindawo yokugcina intsimbi, tapha kuya kuba yimfuneko yokuyila kunye nokucwangcisa iipaneli zokukhanyisa kwiindawo ezithile kuphahla lwentsimbi okanye ukufaka iglasi yokukhanyisa, usebenzisa ukukhanya kwendalo apho kunokwenzeka, kunye nokwenza umsebenzi ongenamanzi ngexesha elifanayo ukwandisa ubomi benkonzo.

Amacandelo amakhulu e-PESB ahlulwe abe ziintlobo ezi-4-

Amacandelo aphambili e-PESB aqulathe i-mainframe, ikholamu, kunye namaplanga-

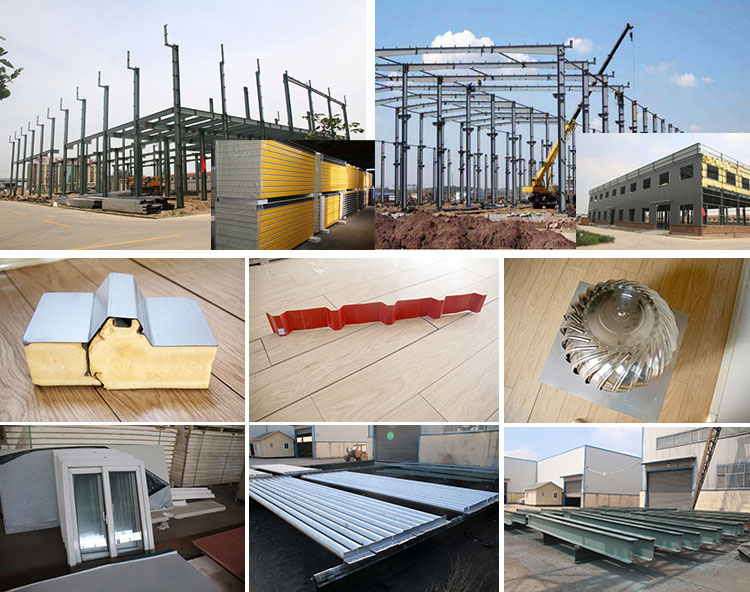

Uyilo oluphambili lubandakanya iifreyimu zentsimbi eziqinileyo zesakhiwo.Isakhelo esomeleleyo se-PESB siquka iikholamu ezicekethekileyo kunye neerafti ezichwetheziweyo.Iiflange ziya kudityaniswa kwi-webs ngokusebenzisa i-fillet eqhubekayo ye-weld kwicala elinye.

Injongo ephambili yeekholomu kukudlulisa imithwalo ethe nkqo kwiziseko.Kwizakhiwo ezenziwe ngaphambili, iikholomu zenziwe ngamacandelo e-I anoqoqosho kakhulu kunabanye.Ububanzi nobubanzi buya kuqhubeka bukhula ukusuka ezantsi ukuya phezulu kwikholamu.

I-rafter yenye yoluhlu lwamalungu olwakhiwo oluthambekileyo (imiqadi) asuka kumqolo okanye ihip ukuya kwi-wall-plate, iperimeter ye-downslope okanye i-eve, kwaye eyilelwe ukuxhasa umgangatho wophahla kunye nemithwalo ehambelana nayo.

I-Purlins, i-Grits kunye ne-Eave struts ngamalungu esibini asetyenziswa njengenkxaso kwiindonga kunye neepaneli zophahla.

Iipurlins zisetyenziswa eluphahleni;Iigrits zisetyenziswa kwiindonga kunye ne-Eave struts zisetyenziswa ekudibaneni kwe-sidewall kunye nophahla.Iipurlins kunye neegirts ziya kubanda "Z" amacandelo kunye neeflange eziqiniweyo.

I-Eve struts iya kuba yi-flange engalinganiyo yamacandelo "C" abandayo.I-Eave struts yi-200 mm ubunzulu kunye ne-104 mm ububanzi beflange phezulu, i-118 mm ububanzi beflange emazantsi, zombini zenziwe ngokunxusene nethambeka lophahla.I-flange nganye inomlomo oqinileyo ongama-24 mm.

Intambo yokuqinisa intambo lilungu eliphambili eliqinisekisa uzinzo lwesakhiwo ngokuchasene nemikhosi kwicala le-longitudinal efana nomoya, iikhreyini, kunye neenyikima.I-diagonal bracing kuphahla kunye neendonga zecala ziya kusetyenziswa.

Amaphepha asetyenziswa ekwakhiweni kwezakhiwo ezenziwe ngobunjineli kwangaphambili yintsimbi esisiseko nokuba yintsimbi egqunywe ngeGalvalume ehambelana ne-ASTM A 792 M ibakala 345B okanye i-aluminiyam ehambelana ne-ASTM B 209M eyintsimbi eqengqelekayo ebandayo, i-tensile ephezulu ye-550 MPA yoxinzelelo lwesivuno, ngokushushu. dip metallic ukutyabeka sheet Galvalume.

Iindawo ezingezizo izakhiwo zezakhiwo ezinjengeebholiti, ii-turbo ventilators, izibane ezibhakabhakeni, izithandwa, iingcango kunye neefestile, iicurbs zephahla kunye ne-fasteners zenza izinto ezincedisayo zesakhiwo sentsimbi esenziwe ngobunjineli.

Ukuhlohla

Siza kubonelela abathengi ngemizobo yokufakela kunye neevidiyo.Ukuba kuyimfuneko, sinokuthumela iinjineli ukuba zikhokele ukufakela.Kwaye, ukulungele ukuphendula imibuzo enxulumene nabathengi nangaliphi na ixesha.

Kwixesha elidlulileyo, iqela lethu lokwakha liye kumazwe amaninzi kunye nommandla ukufezekisa ukufakwa kwendawo yokugcina impahla, iworkshop yentsimbi, iplanti yoshishino, igumbi lokubonisa, isakhiwo seofisi kunye nokunye.Amava atyebileyo aya kunceda abathengi bonge imali eninzi kunye nexesha.